I spent the day yesterday in Davenport Iowa at the QC Co-Lab maker space working on the next step of the plexiglass clock project. This is the progress that I made with my efforts.

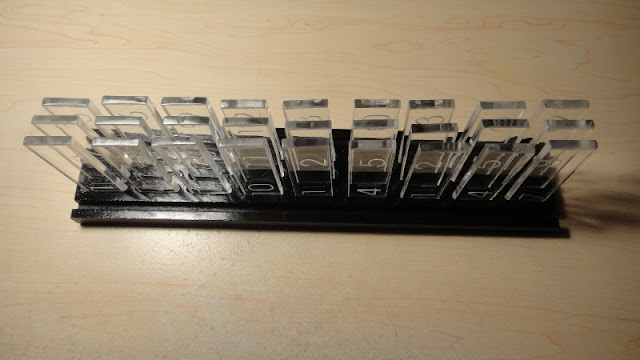

In these three photos you can see the 27 plexiglass (clear acylic plastic) numbered blanks that make up the guts of the clock. In my previous post I engraved these parts and them cut them out using the CNC machine in the workshop. At the Co-Lab I then sanded all the edges of these parts smooth and then took a butane torch and heated the fogged edges. When you cut acrylic plastic and or sand it the clear plastic will fog. When you heat these edges with a torch they become clear once again. This will help make the numbers brighter when the LED lights shine through them.

These two photos give you a good view of the numbered blanks once they have been mounted between the two vertical supports. This was a real trick to get all 27 blanks lined up to with the slots in the mating side of the assembly. It took me at least a half hour and a lot of fiddling to get all the parts in correct position so it all slid together the way I had designed the assembly. With the top and bottom parts not yet mounted the light shining through the assembly allows a nice view of the numbered blanks that are in the assembly.

Here is a good view of the clock inner assembly with the top and bottom plates temporarily taped in place so fiber-glassing could be done.

These last two photos show the fiber-glassing starting to be done to hold the entire assembly together. This was the simplest way to complete this portion of the assembly. I did not want to try to screw it together using wood screws as there was to much of a risk to damage any of the parts. I glassed part of the assembly and let it dry overnight. Then I completed the rest of the glassing this morning to make a strong solid assembly. The holes in the side of the assembly will accept the LED lights that will illuminate the numbered blanks inside. Double LED lights will be used for every number so it should be nice and bright when the clock is running.

I will talk with the tech guys at the QC Co-Lab maker space in Davenport to have them help me with the next step in the assembly. Electronics is not my expertise so I leave that up to guys that are big into that. Just can't be an expert in every field of interest. But I like to try the best I can with what I do know. I can always learn electronics when I run out of other ideas for my projects I am now working on or want to expand my knowledge of design.

I will talk with the tech guys at the QC Co-Lab maker space in Davenport to have them help me with the next step in the assembly. Electronics is not my expertise so I leave that up to guys that are big into that. Just can't be an expert in every field of interest. But I like to try the best I can with what I do know. I can always learn electronics when I run out of other ideas for my projects I am now working on or want to expand my knowledge of design.

No comments:

Post a Comment